PROTECTIVE COATING INSPECTION

Ongoing (Quality Control) and/or hold-point (Quality Assurance) inspections

New installations

Ensure the protective coating is installed per your specification from beginning to end. The coating installation process is comprised of multiple stages: from surface pre-cleaning, to curing of the final coat. It only takes one nonconformity to compromise the longevity of the entire system. Such failures generally occur when measures are not taken to ensure competent, qualified QC personnel are monitoring all the parameters affecting the integrity of the coating system.

Maintenance and repairs

Despite best efforts to ensure 100% conformance to a coating system's installation instructions, imperfections can occur during initial installation. In many cases, they are repairable with proper attention and care. While tempting as a "quick fix", do not fall into the mistake of believing a simple coat of maintenance paint will solve the issue. It will only be temporary solution at best. At worst, you could be masking underlying corrosion that later becomes serious issues. As with new coating installations, maintenance coating calls for compatibility with the service environment, adequate surface preparation, favorable environmental conditions and proper application technique in strict conformance with the coating manufacturer's instructions.

Detailed Reports

There is no Quality Assurance without thorough documentation. Personnel in the industry are ever-changing, but pertinent data of the system installation and maintenance must maintain continuity. Quality reporting aids those that arrive on the scene later. Such documentation also provides a valuable tool for the designer of future corrosion control systems in your facility. Thorough, indisputable documentation is also highly beneficial during investigations and litigation.

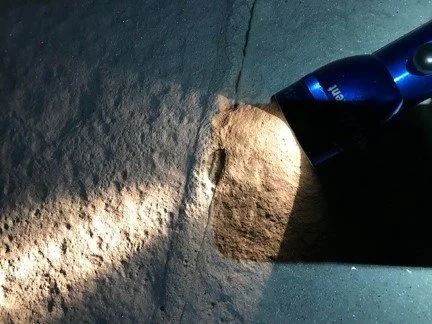

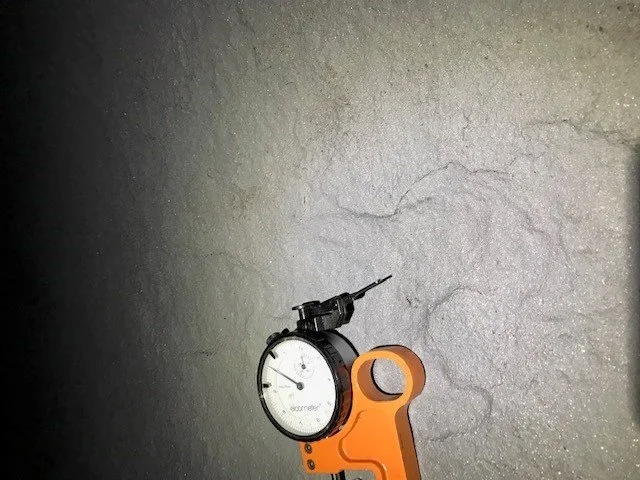

Analysis of Failed Systems

Determine the causes of premature coating failure by ensuring a thorough investigation is performed, documenting probable reasons for the failure. Whether it is due to improper selection of coating material, inadequate surface preparation, insufficient mixing and induction time, or deviation from required dry-film thickness, there is valuable knowledge to be gained and incorporated into your future coating projects.

Disposition of Non-conformances

Identifying nonconformities is the first step. Naturally, the next question is: "How do I address it?". Often times, there are several possible solutions to the same problem. Knowledgeable professionals can help determine and recommend which is best and most economical for you.

COATING SELECTION AND PROJECT DEVELOPMENT

Review and/or development of project specifications

Convert your project vision into concrete, objectively verifiable specifications for realization by outside contractors.

Eliminate potential problems later by removing ambiguity from the beginning, and let us help you ensure your ideas are communicated clearly to all parties.

Material review, research and selection

Choosing the best material for the job is crucial for longevity and success. With many possible solutions comes many hours of research to determine the best answer for your situation.

Let us help you in this process by compiling recommendations from several different sources of expertise.