nasa fred haise A1 test stand thrust drum

Date: September 2020

Location: NASA John C. Stennis Space Center

Client: NASA

The A1 Test stand, recently renamed to the Fred Haise Test Stand, at the NASA Stennis Space Center, is home to several rocket engine supporting numerous programs throughout the years, most recently the RS-25 engine of the SLS program. Housing the rockets in the vertical position ready to be tested is a 33-foot diameter steel thrust drum.

In late 2019, the A1 thrust drum underwent a full recoating in efforts to revamp its aging and deteriorating corrosion protection. One year later, NASA personnel spotted several concerning areas of the new paint flaking, peeling and exhibiting rust bleed through. NASA and supporting contractors then tasked our lead inspector to investigate the cause of the premature coating failures. Upon further inspection, and with the use of destructive testing techniques like Pull-Off Adhesion tests, the team found the failures almost all resulted from inadequate surface preparation on the part of the previous coating contractor. A majority of adhesion test pieces revealed residual rust on the inside surface, indicating the previous coating application was over rusted surfaces. The recommended remediation to NASA was to perform localized coating repairs.

INVESTIGATION

Peeling paint

Rust bleed-through in hard to reach areas

Scattered coating failure

on strut flange of thrust drum

Peeling paint and rust bleed-through

Low accessibility area missed

Several areas found to be well below required dry film thickness (DFT) of 10 mils for this coating system

Adhesion Pull Tester

Measures amount of force required to pull one square inch of paint from substrate (lb/in²)

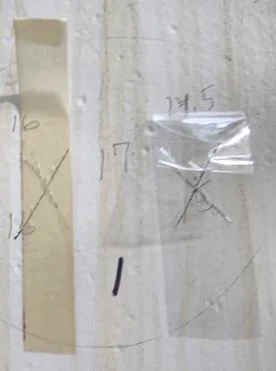

X Cross Hatch Test

Qualitative test of paint adhesion

Back side of paint chips revealing rust. Indicative of inadequate surface cleaning prior to first paint job